The Welded Pipe Seam Normalizer, a cutting-edge solution designed and manufactured by Baoding Chaochang Electromechanical Co, Ltd. As a leading manufacturer specializing in induction heating equipment, we are proud to offer this high-tech product that revolutionizes the normalization process for welded pipe seams.

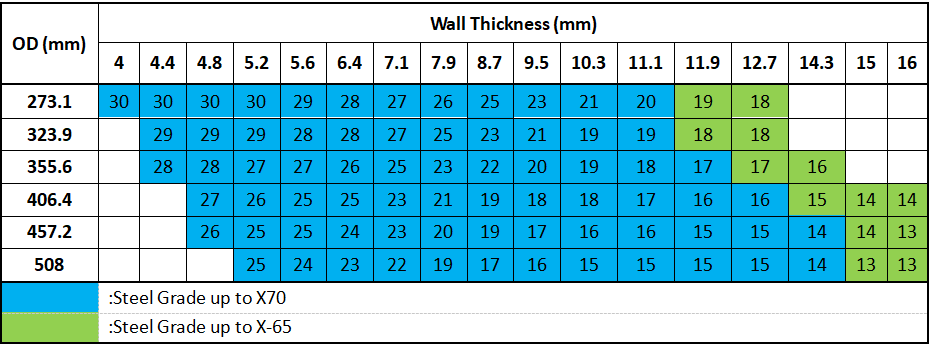

Online welded pipe seam normaliser is mainly used to produce high strength welded pipes such as oil and gas transmission pipes, oil pipes and casing that meet API standards.

- Cooling water pressure: 1.0 Mpa

- Compressed air : 0.4~0.6 Mpa

- The max lifting capacity of single piece during production: 25 T

- The max height of tube mill: 5.5 M

- Power supply: 380 V +/- 10 %

- Phase: 3 Phase Frequency : 50 Hz +/- 0.5 Hz

- Control voltage: 220 Volt Phase: single phase

- Environment temperature: max 40°C

- Humidity: max 90%

The pipe seam induction annealing equipment heats the welding seam just welded to its critical temperature and conducts welding heat treatment of steel pipe to prevent potential cracks in the welding seam.Due to the rapid local heating of the welding seam, the oxidation and deformation of the steel tube are minimized, and the accurate and consistent diathermy also enables the fine grain structure to be obtained in the whole welding seam area. The resulting fine grain structure can ensure the strong and tough steel tube meeting all the requirements of the standard specifications.

The welding area is within 15mm on the left and right sides of the welding seam.

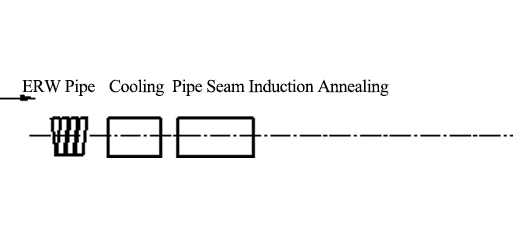

The complete set of equipment is composed of medium frequency heating power supply, water cable, tank capacitor cabinet, inductor, water cooling system, lifting and swinging Angle mechanism, welding seam detector, temperature measuring instrument, operating console and so on.

The plane inductor is used for the annealing equipment to complete the power transfer required by the welding seam heat treatment of steel pipe.

Weld tracking range ±10°, accuracy 1°.

The equipment can effectively avoid the burr of pipe seam.

Steel pipe welding → heating pipe seam upto 930°C→ air cooling

Advanced Normalization Technology:

Our Welded Pipe Seam Normalizer incorporates state-of-the-art technology to achieve exceptional results in the normalization process. It utilizes precise induction heating techniques, allowing for uniform heating and controlled cooling of the welded pipe seam.

Enhanced Seam Integrity:

By subjecting the welded pipe seam to the normalization process, our equipment significantly improves the structural integrity of the pipe. It effectively eliminates residual stresses and refines the microstructure, resulting in enhanced mechanical properties and increased resistance to fatigue and corrosion.

Online Operation:

The Welded Pipe Seam Normalizer seamlessly integrates into the production line, offering online operation. This means that the normalization process can be carried out continuously without interrupting the manufacturing process, resulting in improved efficiency and reduced downtime.

Customizable Solutions:

At Baoding Chaochang Electromechanical Co, Ltd., we understand that each customer's requirements may vary. Therefore, our Welded Pipe Seam Normalizer can be customized to suit specific pipe dimensions, material types, and production capacities. We work closely with our clients to tailor the equipment precisely to their needs, ensuring optimal performance and maximum productivity.

User-Friendly Interface:

Our Welded Pipe Seam Normalizer features an intuitive and user-friendly interface, making it easy for operators to control and monitor the normalization process. The interface provides real-time data on temperature, speed, and other critical parameters, allowing operators to make informed decisions and maintain precise control over the equipment.

Benefit from Baoding Chaochang Electromechanical Co, Ltd.'s expertise and cutting-edge technology with our Welded Pipe Seam Normalizer. By incorporating this innovative solution into your manufacturing process, you can achieve superior welded pipe quality, reduce production costs, and gain a competitive edge in the market.

Choose Baoding Chaochang Electromechanical Co, Ltd. for all your induction heating equipment needs, and let our products and services exceed your expectations. Contact us today to explore how our Welded Pipe Seam Normalizer can revolutionize your production process.

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap