Horizontal shaft should be level,vertical shaft should be straight; Roller position is stable,slider flexible but not swing, and smooth to adjust.

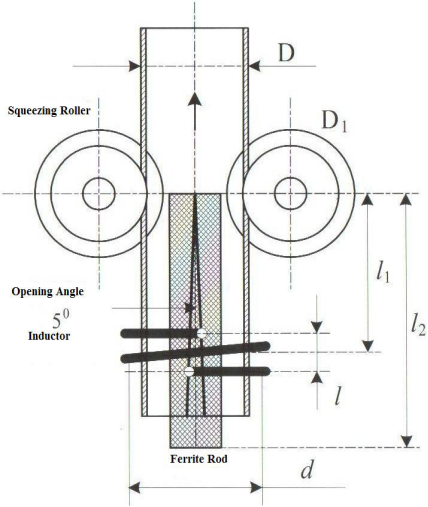

Position of inductor (1 ~ 3 coils ):

Distance from fore-end to squeeze roller center line is 1~1.5 times pipe diameter;inner diameter is 1.2~1.5 times pipe’s outer diameter.

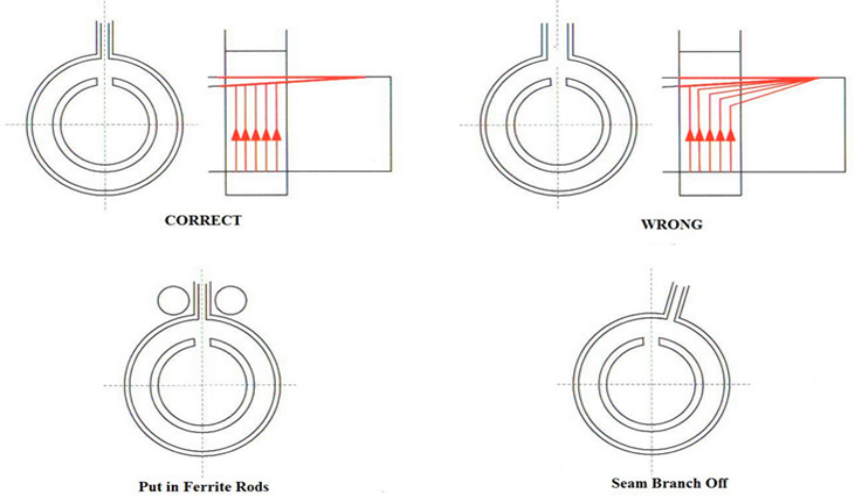

Ferrite rods (impedor)’s position:fore-end line up with the squeezing roller center line,cross section is bigger than 70% inner diameter of tubes, minimum length is longer than the length that squeezing roller diameter plus inductor length.

V opening angle: for carbon steel material , it should be 30o~40o; For stainless steel anonferrous metal , it should be 50o~80o.

Methods to increase welding speed :

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap