Welcome to our comprehensive guide on Solid State High-Frequency (HF) welders! In this article, we will delve into the remarkable capabilities and advantages of these cutting-edge machines that have revolutionized industrial joining processes across various sectors. As a leading authority in the field, we are committed to providing you with in-depth insights into the technology, benefits, and applications of Solid State HF welders. We sell best solid state high frequency welder. If you want to wholesale high quality solid state hf welders, you can browse the product details and contact us to get a quote.

Solid State High-Frequency (HF) welding is a sophisticated method of joining two materials using the application of high-frequency electrical energy. Unlike traditional welding techniques that involve heat generation through an open flame or resistive heating, HF welding employs solid-state power conversion technology to generate and deliver high-frequency energy with exceptional precision.

Solid state high frequency welder's circuit simple, easy installation and energy saving, especially for various round pipe, square pipe, rectangular pipe, oval pipe and special pipe like LTZ. Section welding featured with high efficiency and reliable.

Place of Origin: Hebei, China

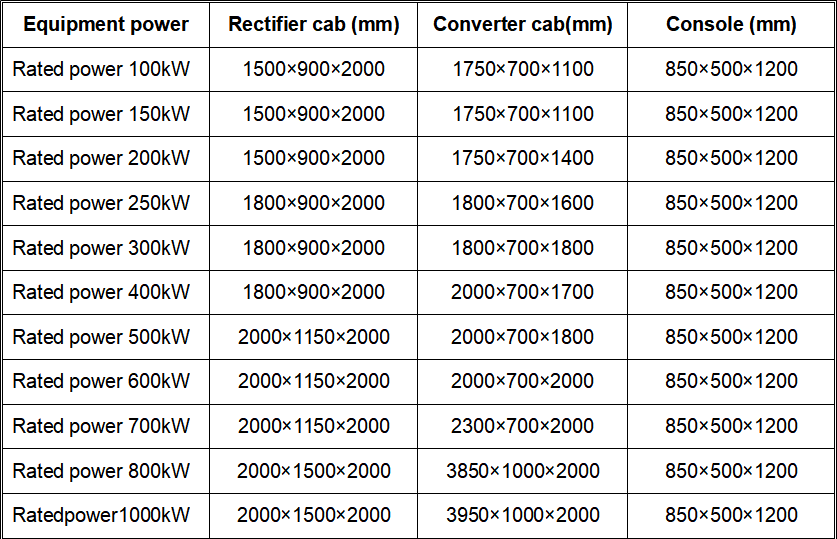

Power: 100KW-800KW

Brand Name: Chaochang

Application: Carbon steel or Galvanized steel

Voltage: 3 phase 380V/50HZ

Certificate: ISO, CE

Usage: Steel tube welding

Warranty: 1 year

Condition: New

Feature: High efficiency and energy saving

Power: 100-800KW

Frequency: 150KHz-600KHz

Characteristic: The low output ripple, the smoothly welding, reaching high output efficiency as high as 85% and still being able to adjust and troubleshoot conveniently.

High-frequency straight welded pipe machine has high processing quality and assembly accuracy, and it can produce high-precision electric welded steel pipe by using reasonable roller path. Novel design, easy and simple operation and maintenance. The high frequency pipe welding machine is designed for high frequency welding of steel pipe, high frequency welding of stainless steel pipe, high frequency welding of aluminum pipe and other pipe high frequency welding applications. The high power inverse model researched by chaochang who single layer power has achieved 120KW as twice as the older one has extended the manufacture ability of high power inverse device.

Coil loading - Unwinding - Strip joining - Accumulator - Forming - HF welding - Weld removal - Cooling - Sizing and straightening - Measuring rollers - Flying saw cutting - Run out conveyor

For your detailed requirements, please contact us.

a. Circuit simple, easy installation.

b. Complete protection, easy maintenance.

c. Harmonic disturbance small, and less pollution electric network

d. Safety and no high-pressure, inductor is not easy tinder on steel pipe.

e. Achieve maximum efficiency more than 85%, energy saving effect obviously, the less cooling water.

f. Output ripple is less than 1%,no welding spatter and the quality of welding seam is well.

g. High reliability and stable operation.

h. Easy to maintain, users can do self-repair.

i. Allow the necessary ,equipment can be dropped rated power to use.

j. All of control boards have universal, non-adjustment .

Provide your design specifications for your workpiece and allow us to generate a quote. Inquiry High Frequency Pipe Welding Machine.

Solid State HF welders offer numerous advantages over conventional welding methods. Let's explore some of the key benefits that have propelled these welders to the forefront of industrial applications:

1. High Precision and Quality:

With the ability to precisely control the application of energy, Solid State HF welders ensure consistent and reliable weld quality. The advanced power conversion technology minimizes variations and defects in the welding process, resulting in superior joint integrity.

2. Increased Efficiency:

By eliminating the need for preheating and cooldown periods, Solid State HF welders significantly reduce overall welding cycle times. This increased efficiency translates to improved productivity and cost savings for businesses.

3. Enhanced Safety:

Solid State HF welders operate without the use of open flames or consumable electrodes, reducing the risk of accidents and injuries. Furthermore, the advanced control systems incorporated in these welders enhance operator safety and minimize the chances of human error.

4. Versatile Applications:

From automotive and aerospace industries to medical device manufacturing and consumer electronics, Solid State HF welders find applications across a wide range of industries. Their versatility enables the joining of various materials, including metals, plastics, and composites, offering flexibility and adaptability to meet diverse industry requirements.

To better understand how Solid State HF welders operate, let's explore the fundamental working principles involved in this innovative technology:

1. Power Conversion:

Solid State HF welders employ state-of-the-art power conversion technology to transform the incoming electrical power into high-frequency energy. This process ensures efficient energy utilization and enables precise control over the welding parameters.

2. Electrode Configuration:

In Solid State HF welding, two electrodes apply pressure to the materials being joined. These electrodes may take different shapes depending on the specific welding requirements, such as flat, concave, or profiled.

3. High-Frequency Heating:

As the electrodes come into contact with the materials, the high-frequency energy is transferred to the joint area, rapidly heating it. The controlled application of heat softens the materials, allowing them to fuse together upon cooling.

4. Monitoring and Control:

Advanced control systems integrated into Solid State HF welders constantly monitor critical parameters such as voltage, current, and power. This real-time monitoring ensures optimal performance and enables adjustments for different materials and welding configurations.

Solid State HF welders have found widespread adoption in numerous industries due to their exceptional performance and versatility. Let's explore some of the prominent applications:

In the automotive sector, Solid State HF welders are instrumental in joining components like fuel tanks, exhaust systems, and body panels. The high precision and quality of the welds contribute to enhanced vehicle safety and structural integrity.

The electronics industry benefits from Solid State HF welding for manufacturing components such as batteries, circuit boards, and connectors. The ability to join dissimilar materials, including metals and plastics, makes these welders indispensable in the production of consumer goods.

Solid State HF welders are extensively used in the production of medical devices like catheters, sensors, and surgical instruments. The high precision and reliability of the welding process ensure the integrity and longevity of these critical healthcare components.

Are you seeking the pinnacle of precision, efficiency, and reliability in your industrial joining processes? Look no further than Baoding Chaochang Electromechanical Co, Ltd.'s Solid State High-Frequency (HF) Welders. As a leading manufacturer specializing in induction heating equipment, we proudly present our cutting-edge technology that is set to transform the way you weld.

Our Solid State HF Welders have been meticulously engineered to deliver exceptional results across a wide range of applications. With our state-of-the-art research and development facilities, we have combined innovation and expertise to create welders that meet the highest standards of performance and quality.

At Baoding Chaochang Electromechanical Co, Ltd., we understand the critical importance of precision and weld quality in your operations. Our Solid State HF Welders offer unparalleled control over the welding process, ensuring consistent and reliable joint integrity. With advanced power conversion technology, variations and defects are minimized, resulting in superior welds that meet the most stringent industry requirements.

Time is money, and our Solid State HF Welders are designed to optimize your production cycles. By eliminating the need for preheating and cooldown periods, these welders significantly reduce overall welding times, enhancing efficiency and productivity. Experience faster turnaround times and seize opportunities for increased output, all while maintaining the highest standards of weld quality.

Safety is a paramount concern for any enterprise, and Baoding Chaochang Electromechanical Co, Ltd. understands this well. Our Solid State HF Welders operate without open flames or consumable electrodes, mitigating the risks of accidents and injuries in your workplace. Additionally, the integration of advanced control systems ensures operator safety and minimizes the chances of human error, promoting a secure and reliable working environment.

Our Solid State HF Welders are engineered for versatility, making them suitable for a wide array of industries and applications. Whether you are in automotive manufacturing, electronics production, or medical device fabrication, our welders can seamlessly join various materials, including metals, plastics, and composites. Embrace the flexibility and adaptability of our welders to meet the unique requirements of your industry.

With Baoding Chaochang, you are partnering with a trusted industry leader. Our company has established itself as a beacon of excellence, bringing together research, development, production, marketing, and technical service expertise to provide high-tech modern induction heating machines. We are committed to delivering the highest quality products and unparalleled customer support, ensuring your complete satisfaction.

Upgrade your industrial joining processes with Baoding Chaochang Electromechanical Co, Ltd.'s Solid State High-Frequency (HF) Welders. Contact us today to explore how our cutting-edge technology can revolutionize your operations and take you to new heights of success.

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap