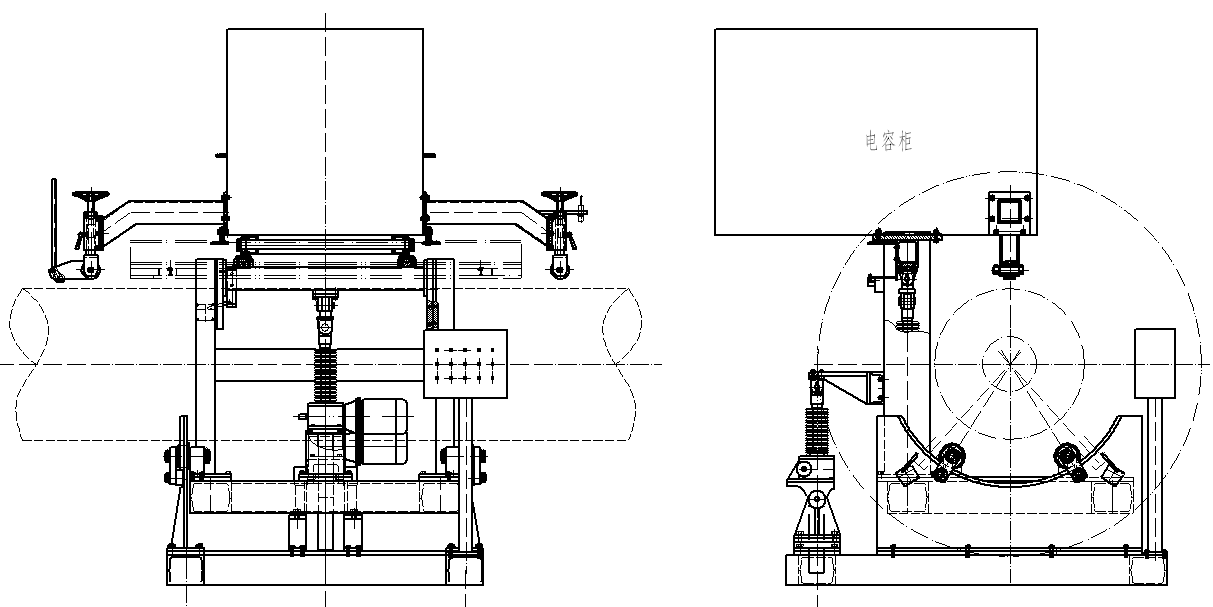

The adjusting sensor device for pipe seam heat treatment is placed at the bottom and back of the welded pipe production line, which is used to support the capacitor cabinet and fix the sensor. The device has on-line adjustment function, which can realize automatic adjustment in three directions.Through the automatic control system to realize the sensor rise and fall and swing around the center of the steel tube function, to adjust the relative distance between the sensor and the steel tube, to achieve welding seam tracking and the sensor quickly avoid function.At the same time, the manual adjustment of steel tube guide press wheel can be realized.

1. the adjustment device is equipped with guide press wheel adjustment mechanism on both sides of the inductor. By manually rotating the adjustment hand wheel, the guide limit press wheel of the steel tube can be raised or lowered, so that the gap between the inductor and the steel tube can reach the optimal state.When the gap is found to be deviated, the gap can be manually adjusted without stopping the machine.The guide roller is designed with groove structure to reduce heat loss, and the roller bearing is self-lubricated with high temperature resistance and water cooling, which fully guarantees the working reliability of the roller.

2. the automatic control system of the adjustment device can realize the functions of quick avoidance of the inductor and slow rise and fall of the inductor in the vertical direction (the response range of the workpiece is 273.1 ~ 508.0mm of steel tube diameter).Lifting adjusting device sensors rely on the inverter control ac motor as the driving force, through the spiral elevator (JWM050 - UM - H300JI - Ⅰ - YVF1.1 - C) transmission mechanism, realize the capacitance ark and the fast and slow lifting function of the sensor components, to meet the needs of the different diameter adjustment group (slow movements) and sensor quickly give way (quick lifting) function.After the sensor is raised quickly, the return position sends a signal through the detection device, making the sensor return to the original accurate working position.

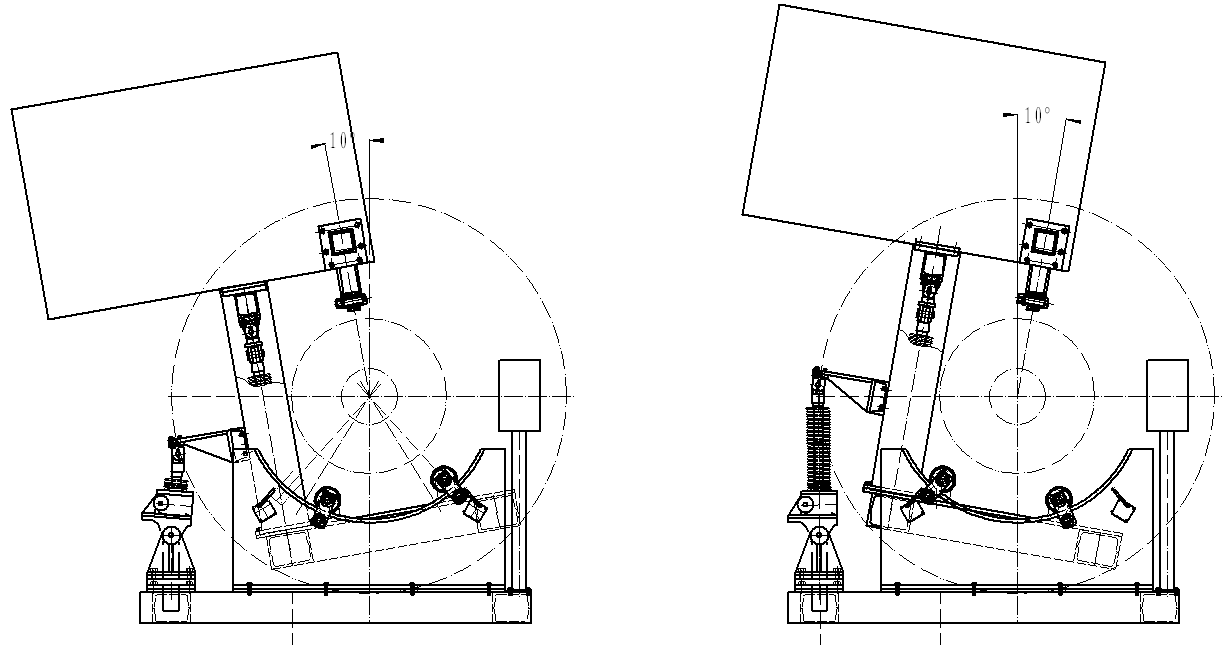

3. the adjusting device can realize the weld seam tracking function by adjusting the swing Angle of the inductor.

Pendulum Angle adjustment device arc guide oriented surface, through precision screw hoist and inspection agencies, when steel pipe welding seam deviation sensor center, through the precise screw elevator drive the tilting mechanism to realize the sensor around the steel pipe center swing, swing Angle plus or minus 10 °, avoided due to the steel pipe welding seam deviation caused by the heating area of weld heat treatment is not completely.

4. In order to prevent the damage of the sensor head caused by the burr and foreign matter hitting the pipe body and scraping the sensor head, the device is equipped with the inductor anti-collision protection device at the front of the guide roller at the pipeline inlet.Through the action of lever amplifying mechanism and detection switch, the sensor can be raised quickly, and the damage of sensor head and abnormal ignition of sensor caused by welding seam burr and foreign matter collision are fully avoided.Make the inductor quickly deviate or approach the weld position of steel pipe.When the burr passes through the sensor, the sensor quickly falls back to the original position (the detection switch is installed in the original position).

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap